China, Japan, and Korea are responsible for 88% of total global LIB cell manufacturing capacity for all end-users applications. The most LIB cell manufacturing facilities are primarily located in Asia.

These countries are also home to a significant share of LIB-specific materials manufacturing capacity, including that for cathodes (85% of global capacity), anodes (97%), separators (84%), and electrolytes (64%). This concentration of cell manufacturing capacity and upstream supply chains contributes to LIB industrial clusters in each of these countries. The numbers do not include new start up manufactures.

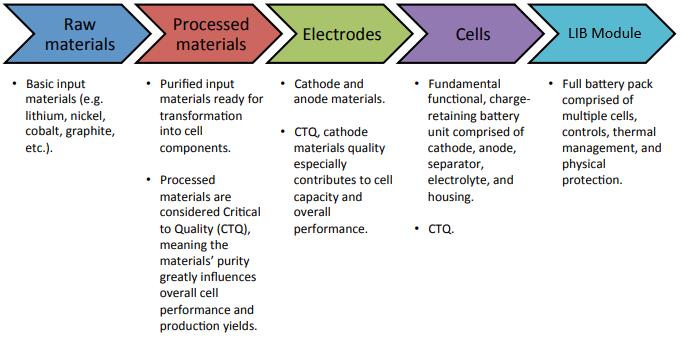

LIB Supply Chain:

Major components of the automotive LIB value chain include processed materials for electrodes and other components. With respect to vertical integration, various manufacturers are employing different approaches. Battery cell pack design and production is typically performed by automakers themselves. The LIB electrode materials, processed materials and sealed cells can be shipped anywhere.

The LIB manufactures are made up of several processing steps and performed in separate facilities; Raw materials such as lithium and graphite are mined, then processed for purity or specific Composition, The processed materials are used to manufacture electrodes, which are key components of LIB cells. Electrodes and cells are typically produced in the same facility, the Cells, along with other components, are assembled into a complete LIB power module or power cell packs.

Market Considerations:

The actual selling prices may be driven by market factors other than manufacturing costs, especially in early stages of high-growth industries such as large format LIB cells. Large format LIBs manufacturers have initially rated the cells below their actual capacities capabilities in order to ensure that they meet or exceed their projected marketed requirements. They would also increasing their production capacity normalized price ($/kWh).

The majority of automotive LIB modules and cell production is also currently located in Asia, and is owned by firms that produce LIB power cells for the consumer electronics markets. They leverage significant advantages in the automotive market, which include robust supply chains suppliers leverage, strategic partnerships, diversified sales channels, higher mark ups and other manufacturing advantages. However, while Asian firms currently dominate the market, price competitive production may be possible from other countries.

eMpasys is a cutting edge Alternative/Renewable Technology Engineering company that was establish in 1998, we provide, customized LIB design solutions and develop various renewable technology environmentally conscious solutions. http://www.empasys.net

© eMpasys